| Optimization of a mechanical heart

valve |

|

The heart has four chambers. The upper

two are the right and left atria. The lower two are the right

and left ventricles. Blood is pumped through the chambers,

aided by four heart valves. The valves open and close to let

the blood flow in only one direction.

What are the four heart valves?

- The tricuspid valve is between the right atrium and right

ventricle.

- The pulmonary or pulmonic valve is between the right ventricle

and the pulmonary artery.

- The mitral valve is between the left atrium and left ventricle.

- The aortic valve is between the left ventricle and the

aorta.

Each valve has a set of flaps (also called leaflets or cusps).

When working properly, the heart valves open and close fully.

Heart valves don't always work as they should. A person can

be born with an abnormal heart valve, a type of congenital

heart defect. Also, a valve can become damaged by

- infections (e.g. infective endocarditis)

- changes in valve structure in the elderly

- rheumatic fever

|

|

|

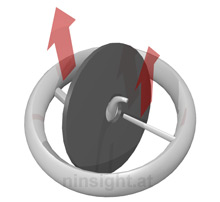

A mechanical (or artificial) heart valve

is a man-made device that is used to replace one of a patient’s

own damaged or diseased heart valve that cannot be repaired.

A biological valve, from either an animal (xenograft) or a

deceased human donor (allograft) may also be used to replace

the patient’s original valve.

In most cases, the use of a mechanical heart valve can lengthen

or even save a patient’s life. The valves are durable

and can last 30 years or longer. However, there is a risk

of complications, and most patients will need to take anticoagulants

for the rest of their lives to reduce the risk of blood clot

formation.

Here we perform a numerical study of a valve construction

based on a curved central guide strut and a flat disc. This

has two advantages: (i) It allows assembly of the valve and

disc without imparting stress on the valve housing and (ii)

it allows the disc to move out of the annular plane (which

is the tightest constricture of the resultant outflow tract).

This type of valve is produced by Medtronic. |

|

| Turbulence in the cardiovascular system

leads to higher flow resistance, resulting in increased pressure

gradients. Furthermore, elevated levels of turbulent shear

stresses may create hemolysis or platelet activation [1],

[5]. This may in turn lead to thrombosis [8] and embolism.

It was also shown that turbulent shear stresses can be associated

with the development of aortic aneurysms [3], [6].

The damage done to red blood cells can be described as a function

of spatial distribution, exposure time and magnitude of turbulent

shear stresses. In particular, in [7] and [9] the critical

parameters of turbulent shear stress were identified, which

lead to lethal or sublethal damage of blood cells.

The goal of an optimal heart valve is to retain a near physiologic

turbulence profile. The benefits are minimal pressure gradients

and very low levels of thrombosis and thromboembolism. This

was experimentally prooved for the Medtronic Hall valve in

[2].

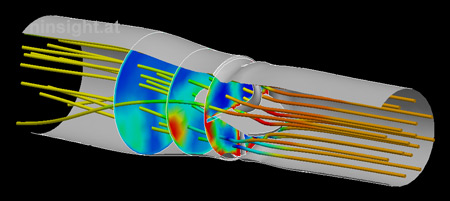

To achieve this design goal, computational fluid dynamics

simulations are of great advantage. The valve and the adjacent

arteries were modeled using NURBS to facilitate (i) adaptive

mesh refinement and (ii) a parametric geometrical model which

is suitable for design optimization. The fluid zone was meshed

automatically by a hexahedral mesh using approx. 400.000 elements.

The fluid problem was modeled using a non-Newtonian model

which was solved using a modified SIMPLE algorithm. The moving

bodies were considered using fluid structure interaction considered.

Thereby, the arterial wall is simulated as a hyperelastic

medium and the valve disc as a rigid, but movable body. The

results of the simulation are shown in Fig. 1 and 2.

|

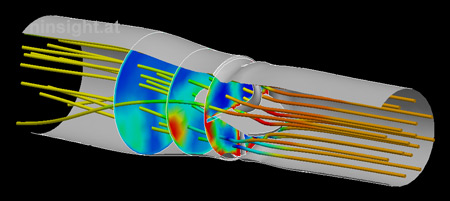

Fig. 1: CFD

simulation of the mechanical heart valve. The image

depicts the flow situation at the systolic phase (the

valve is fully opened under 75°). Streamlines are

colored by the local pressure. Section planes show the

turbulent dissipation. |

|

|

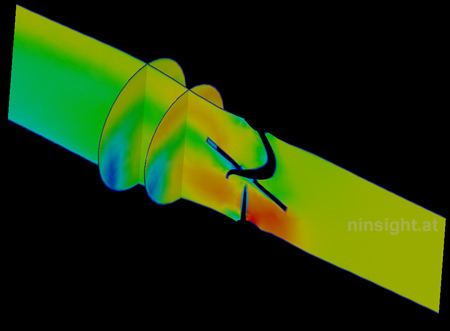

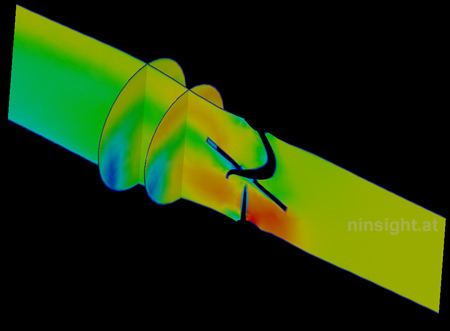

Despite a common belief in a symmetrical

(i.e., bullet-shaped) flow pattern in the ascending aorta,

research has confirmed that natural aortic flows are eccentric—with

the region of highest velocity occurring in the non-coronary

sinus [Paulsen et al.].

|

| Fig. 2: Velocity magnitude at fully

opened valve (three representative sections). |

|

|

- Kroll

MH, Hellums JD, McIntyre LV, et al. Platelets and Shear

Stress. Blood 1996;88:1525-41.

- Kleine

P, Perthal M, Nygaard H, et al. Medtronic Hall versus St.

Jude Mechanical Aortic Valve: Downstream Turbulences with

Respect to Rotation in Pigs. J Heart Valve Dis 1998;7:548-55.

- Nichols

WW, O'Rourke MF. McDonald's Blood Flow in Arteries. Theoretic,

Experimental, and Clinical Properties. 3rd ed. Philadelphia:

Lea & Febiger, 1990;54-71.

- Paulsen

PK, Nygaard H, Hasenkam JM, et al. Analysis of Velocity

in the Ascending Aorta in Humans. A Comparative Study Among

Normal Aortic Valves, St. Jude Medical and Starr-Edwards

Silastic Ball Valves Int. J Artif Org 1988; 11:293-302.

- Ruggeri

ZM. Mechanisms of Shear-Induced Platelet Adhesion and Aggregation.

Thromb Haemost 1993:70:119-123.

- Stein

PD, Sabbah HN. Hemorheology of Turbulence. Bioheol 1980;17:301-19.

- Tillmann

W, Reul H, Herold M, et al. In Vitro Wall Shear Measurements

in Aortic Valve Prostheses. J Biomech 1984;17:263-79.

- Yoganathan

AP, Wick TM, Reul H., The Influence of Flow Characteristics

of Prosthetic Heart Valves on Thrombus Formation. I: Butchart

EG, Bodner E (eds.) Current Issues in Heart Valve Disease:

Thrombosis, Embolism and Bleeding. London: ICR, 1992;123-48.

- Yoganathan

AP, Woo Y-R, Sung H-W. Turbulent Shear Stress Measurements

in Aortic Valve Prostheses. J Biomech 1986;19:433-42.

|