Simulation of a natural human aortic heart valve

|

| The human aortic heart valve |

|

|

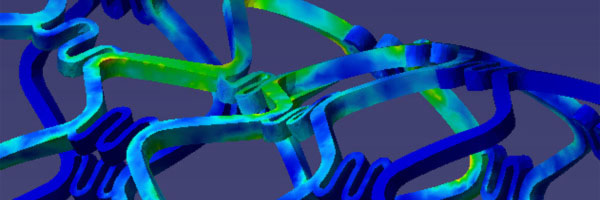

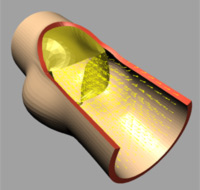

Image 1: Schematic sagittal

cross section of the human heart showing the aortic valve. |

|

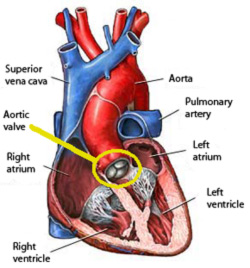

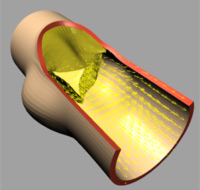

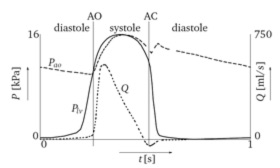

Image 2: Distribution of

the aortic pressure (Pao, dashed line) and left ventricular pressure

(Plv, solid line) during the cardiac cycle. The associated flow

is the curve denoted with Q. The symbols AO and AC denote the instants

of valve opening and complete valve closure, respectively. |

The aortic valve is one of the four valves which control

the blood flow through the heart. It is located at the outlet of the left

ventricle at the beginning of the ascending aorta (see yellow circle,

Image 1). The healthy valve opens with minimal resistance and closes to

prevent back flow into the ventricle.

The cardiac cycle can be divided into a systolic and diastolic interval,

see Image 2. During systole an isochoric contraction of the left ventricle

is followed by the ejection of blood into the aorta. During this interval

the aortic valve remains open.

At diastole an isochoric relaxation precedes a filling of the left ventricle

with blood from the atria. During this interval the aortic valve remains

closed. Both mechanical and kinematic aspects are involved in valve functioning

and differ in importance during the course of the cardiac cycle.

In one cardiac cycle three main phases can be distinguished in valve performance:

(i) the opening and (ii) closing phases during systole and (iii) the closed

phase during diastole. For a healthy valve, the opening interval is very

fast (25 to 35 [ms]). The leaflets begin to bulge towards the aorta wall

just before ventricular ejection begins. At the time when the flow in

the ascending aorta has reached 75% of its maximum, the valve is completely

open. In the case of normally working heart valves, the fluid flow remains

laminar, although the Reynolds number reaches up to 4500 at peak flow

[2]. Only when a valve exhibits a malfunctioning, some turbulence might

be expected [1]. |

| Morphology and numerical model |

|

|

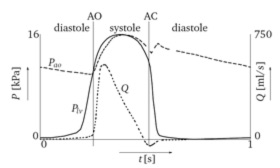

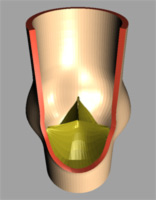

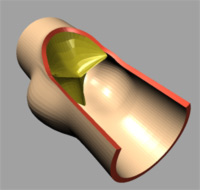

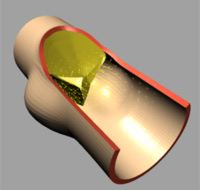

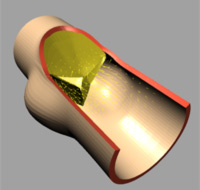

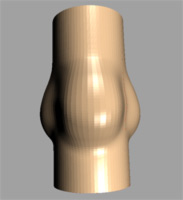

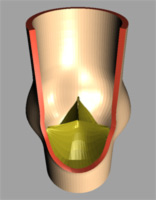

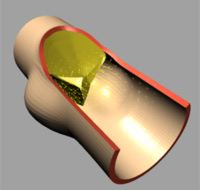

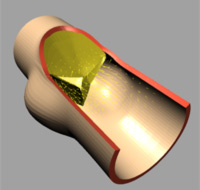

| Image 3: Geometrical model of the aortic heart

valve (left full model, right after dissection). |

The natural valve consists of three highly flexible

leaflets and three sinus cavities, see Image 3. Each leaflet can be divided

in two functional areas:

The area near the free edge is known as the coaptive area (also called

the lunulea because of its semilunar shape). When the valve is closed

the outlet orifice of the left ventricle is sealed because the lunuleae

of adjacent leaflets touch each other. In the middle of the free edge

of each lunulea a structural thickening (’nodulus of Arantius’)

is located. Presumably, it acts as a structural reinforcement, allowing

a significant reduction in the height of the lunulea without causing central

regurgitation during a closed valve configuration.

The remaining, non-coaptive area of the leaflet surface is referred to

as the load bearing portion. This part constitutes a fiber-reinforced

composite texture of elastin. The fibers consist mainly of collagen embedded

in a matrix of endothelial cells. In particular, this texture has a three-layered

structure: The ventricularis at the ventricular surface contains

elastin and collagen fibers, the spongiosa (middle layer) contains

acid mucopolysaccharides and some collagen fibers, the fibrosa

(near the aortic surface) contains a dense network of collagen fibers.

A similar layered structure is present in the lunulea, however, the arrangement

of the fibers may be very irregular.

For the numerical model, a short

segment of the aorta with the three sinus cavities as well as the leaflets

were geometrically modeled using NURBS. All tissue components are simulated

mechanically using an anisotropic material model to consider the elastin-collagen

fiber matrix on a multi layered basis. For fluid structure interaction

a Lagrange multiplier based fictitious domain formulation [1] is integrated

within the finite element method. Contact interaction between the leaflets

is based on the publication [3]. The key features of this numerical strategy

are:

- Conventional mathematical discriptions

- Fully coupled approach

- Interaction through kinematical constraints

|

|

|

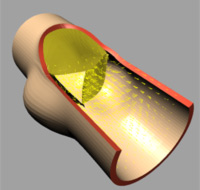

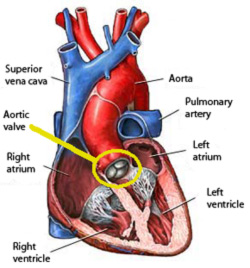

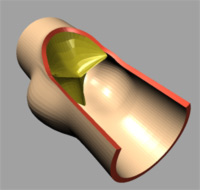

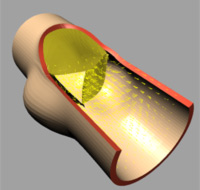

| (a) t=0.0 [s] |

|

|

| (b) t=0.02 [s] |

|

|

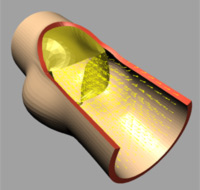

| (c) t=0.04 [s] |

|

|

| (d) t=0.1 [s] |

|

|

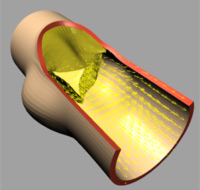

| (e) t=0.3 [s] |

|

|

| (f) t=0.5 [s] |

|

|

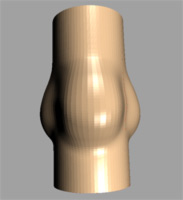

| Image 4: Fluid dynamics during systole. |

The deformation of both the leaflets and the ascending aortic wall as

well as the velocity vector field is given in Image 4 (a) to (f). In frame

(a) the valve is shown in its initial (stress free) configuration, corresponding

to the closed position. During the acceleration phase (frame (b)) a forward

flow is observed throughout the whole fluid domain, including the sinus

cavity (i.e. wash-out). For the fully opened valve (frame (d)) the flow

is concentrated in the center. Almost no flow can be seen in the sinus

cavity. At the moment of complete valve opening, however, the flow has

started to decelerate already. During the deceleration phase recirculation

at the leaflet free edge precedes vortex development in the sinus cavity

and the valve is closed again (frames (e) and (f)).

|

|

The numerical simulation of

a human aortic heart valve provided detailed insight into the normal flow

pattern. This information is indispensible when it comes to designing

artificial heart valves, which aim to generate a flow pattern similar

to the natural valve. The presented strategy also allows to study innovative

designs of artifical valves under arbitrary conditions. |

|

[1] De Hart, J., Peters, G.W.M., Schreurs, P.J.G.,

Baaijens, F.P.T., A three-dimensional computational analysis of fluid-structure

interaction in the aortic heart valve, J. of Biomechanics, 2001.

[2] Nerem, R.M., Seed, W.A., 1972. An in vivo study of aortic flow disturbances.

Cardiovascular Research, 6(1): 1-14.

[3] M. Stadler, G. A. Holzapfel and J. Korelc, Cn-continuous

modeling of smooth contact surfaces using NURBS and application to 2D problems,

Int. J. Numer. Meth. Engng., 57:15 (2003), 2177-2203.

|