The Challenge

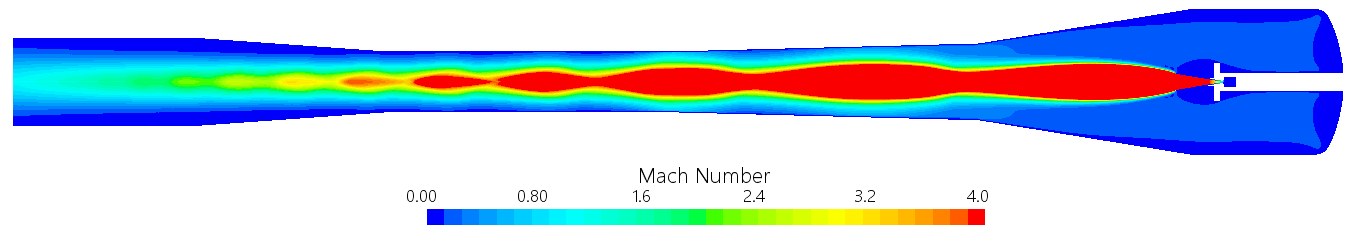

Vacuum ejector pumps are utilized in steel production to remove the atmosphere and extract contaminants. High pressure steam is injected via a Laval nozzle. It expands and accelerates to super sonic speed. Thereby it entrains another gas and effectively reduces atmospheric pressure down to around 1.3 mbar. The shape of the ejector is crucial to guide the flow to supersonic speeds inside the throat.

Solution

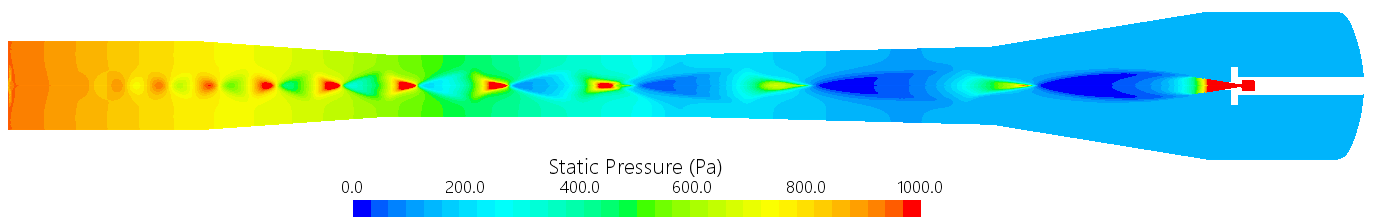

The shape of the ejector and the Laval nozzle were optimized to accurately control the super-sonic multi phase flow (gas and steam). The design of the ejector triggers a succession of expansion shock waves which help effectively reduce the pressure.

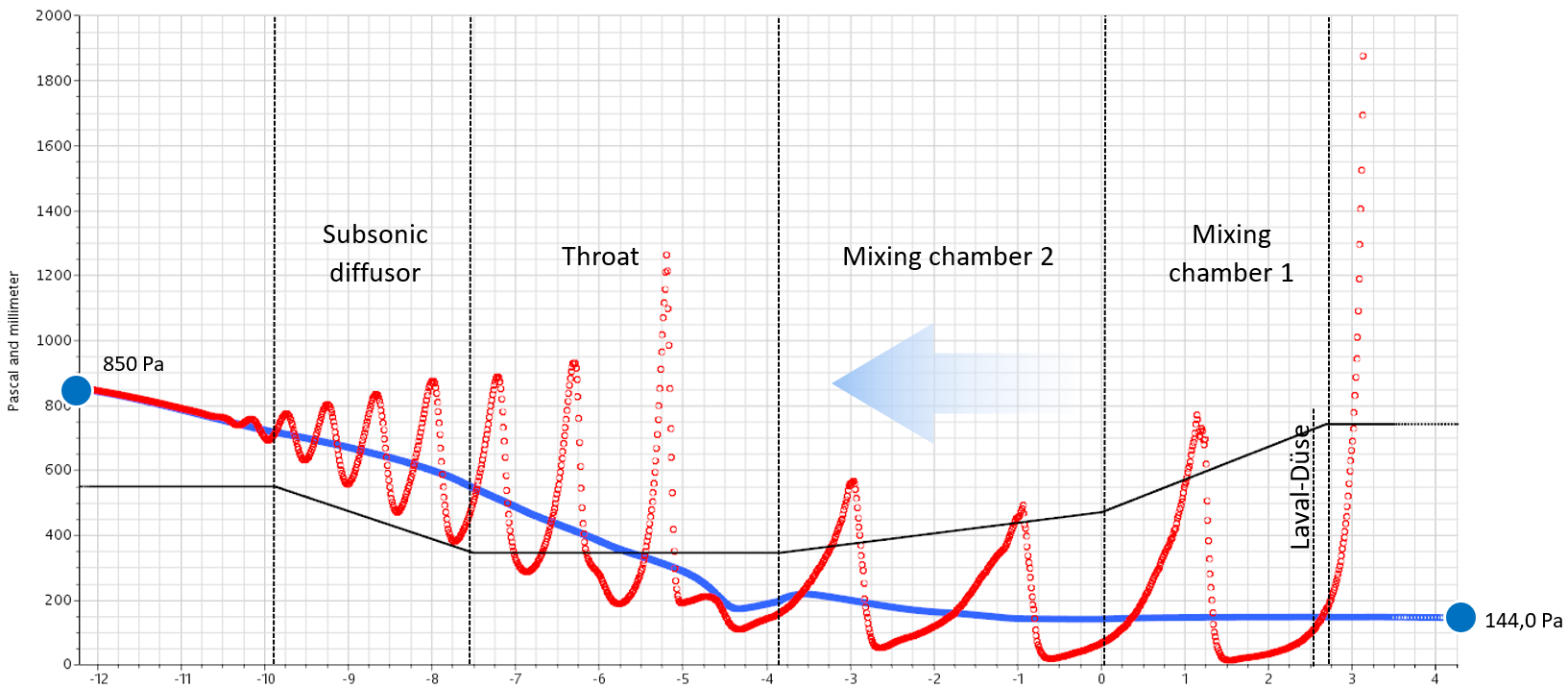

Static Pressure

Note the classic diamond structure of compression/expansion waves which are responsible for high efficiency of the vacuum pump..

Mach number

The Laval nozzle efficiently accelerates the steam up to around Mach 8. Entrainment of atmospheric gas happens on the perimeter of the supersonic stream.

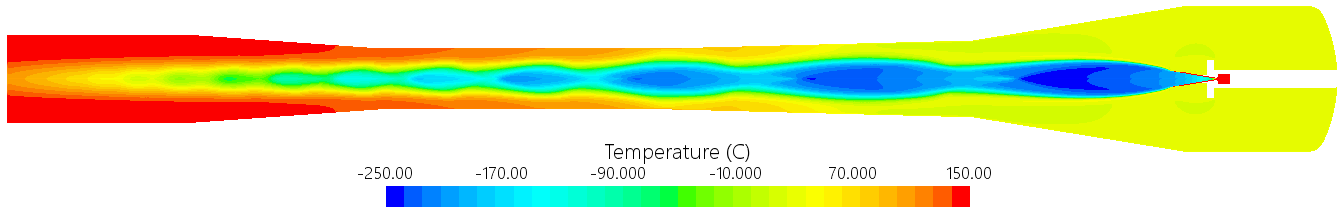

Temperature

During expansion the steam cools down to around -250 °C. Due to friction at the shock waves and mixing with the entrained gas, the outlet reaches a temperature of around 150 °C.